Structural Safety Verification is a crucial process ensuring the safety and resilience of electric and hybrid vehicles (EHV) in collisions. Leveraging advanced technologies like CAD, FEA, ultrasonic, and x-ray inspections, this meticulous procedure identifies weak points, complies with safety standards, and considers unique vehicle characteristics. Computer simulations predict structural behavior under stress, enabling efficient repairs while preserving design integrity. The ultimate goal is to create safe, reliable, environmentally friendly vehicles for sustainable transportation solutions. Regular maintenance, including inspections and techniques like paintless dent repair, is vital for preserving the vehicle's structural integrity over time.

In today’s electric and hybrid vehicle landscape, ensuring structural safety is paramount. This article delves into the crucial aspect of structural safety verification procedures, highlighting their significance for passenger protection. We explore key considerations for maintaining structural integrity in these innovative vehicles. From understanding the definition and importance to examining advanced testing protocols and future trends, this guide provides insights into enhancing structural safety across the industry. Discover how cutting-edge technologies are revolutionizing EV/HV vehicle construction.

- Understanding Structural Safety Verification

- – Definition and significance in electric and hybrid vehicles

- – Key considerations for structural integrity

Understanding Structural Safety Verification

Structural Safety Verification is a critical process that ensures the integrity and resilience of electric and hybrid vehicles’ structures in the event of a collision. It involves meticulous inspections, simulations, and testing to identify potential weak points and ensure compliance with safety standards. This comprehensive procedure goes beyond conventional methods by considering the unique characteristics of advanced vehicle designs, such as lightweight materials and complex systems integration.

By incorporating cutting-edge technologies like computer-aided design (CAD) and finite element analysis (FEA), structural safety verification enables engineers to predict how a vehicle will behave during a collision. This foresight is crucial in mitigating risks associated with accidents and ensuring the safety of both occupants and pedestrians. Moreover, it aids in the efficient allocation of resources for collision repair services, including car paint repair and dent removal, by minimizing damage and optimizing the use of replacement parts.

– Definition and significance in electric and hybrid vehicles

In the realm of electric and hybrid vehicles (EHV), structural safety verification procedures are paramount to ensuring the vehicle’s integrity and passenger protection. These processes involve rigorous testing and analysis to verify that the vehicle’s frame, body panels, and components can withstand various loading conditions, impact scenarios, and environmental stresses unique to EHV technologies. The significance of these verifications lies in mitigating risks associated with accidents, electrical failures, and component degradation, which could lead to hazardous situations due to the high-voltage systems and sensitive battery packs incorporated in these vehicles.

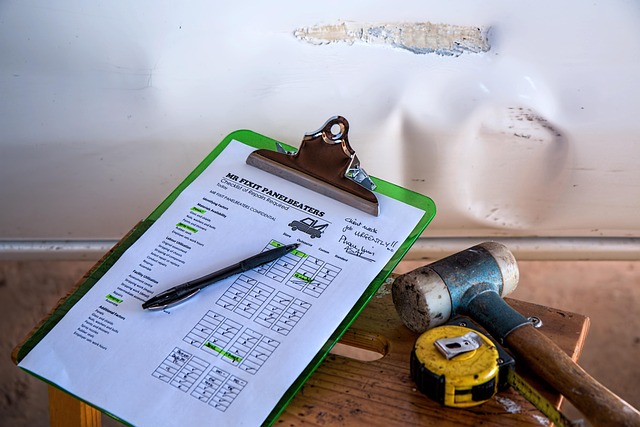

Structural safety verification encompasses a multi-faceted approach, including non-destructive testing methods like ultrasonic and x-ray inspections, as well as computer simulations to predict structural behavior under stress. Proper implementation of these procedures not only safeguards passengers but also facilitates efficient repairs and restoration processes, such as auto body restoration and dent removal, while maintaining the vehicle’s original design integrity. This ensures that EHVs are safe, reliable, and environmentally friendly, contributing to the growing adoption of sustainable transportation solutions.

– Key considerations for structural integrity

When it comes to structural safety verification procedures for electric and hybrid vehicles, ensuring structural integrity is paramount. Key considerations include rigorous testing of all critical components to withstand various types of stresses and forces, both during normal operation and in the event of a vehicle collision. This involves comprehensive simulations and real-world testing to verify that the vehicle’s frame, body panels, and other structural elements maintain their integrity under diverse conditions.

Additionally, factors like weight distribution, material strength, and energy absorption play crucial roles in achieving optimal structural safety. Modern techniques such as advanced composite materials and intelligent design strategies are increasingly employed to enhance crashworthiness without compromising aesthetics or performance. Maintenance practices, including regular inspections and timely repairs, whether through traditional methods or innovative approaches like paintless dent repair, contribute to preserving the vehicle’s structural integrity over its lifespan, thus ensuring safer operations for drivers and passengers alike.

Structural safety verification is a paramount process in ensuring the integrity and reliability of electric and hybrid vehicles. By understanding and adhering to these procedures, manufacturers can guarantee passenger safety and vehicle performance. With ongoing advancements in technology, maintaining robust structural safety standards remains essential for the widespread adoption of electric mobility. This comprehensive approach ensures that every component undergoes rigorous testing, fostering a culture of safety within the industry.